Key Takeaways

-

A simple mechanical impulse exposes how strongly a material resists internal motion.

-

The resulting vibration patterns reveal stiffness, bonding quality, and hidden flaws.

-

This technique works without cutting, breaking, or altering the part.

-

It’s used in aerospace, automotive, additive manufacturing, and even product authentication.

Why Tapping Matters

Most parts don’t fail because they look wrong—they fail because something inside them isn’t right. Cracks, voids, weak bonds, or uneven stiffness—these internal inconsistencies often go undetected until it’s too late. Destructive tests help, but they destroy the part and only tell you about the one you tested—not the one going into service.

Impulse excitation changes that.

By tapping a part and listening to how it vibrates, you can measure its internal consistency directly—without damaging it.

How Resonance Frequency Testing Works

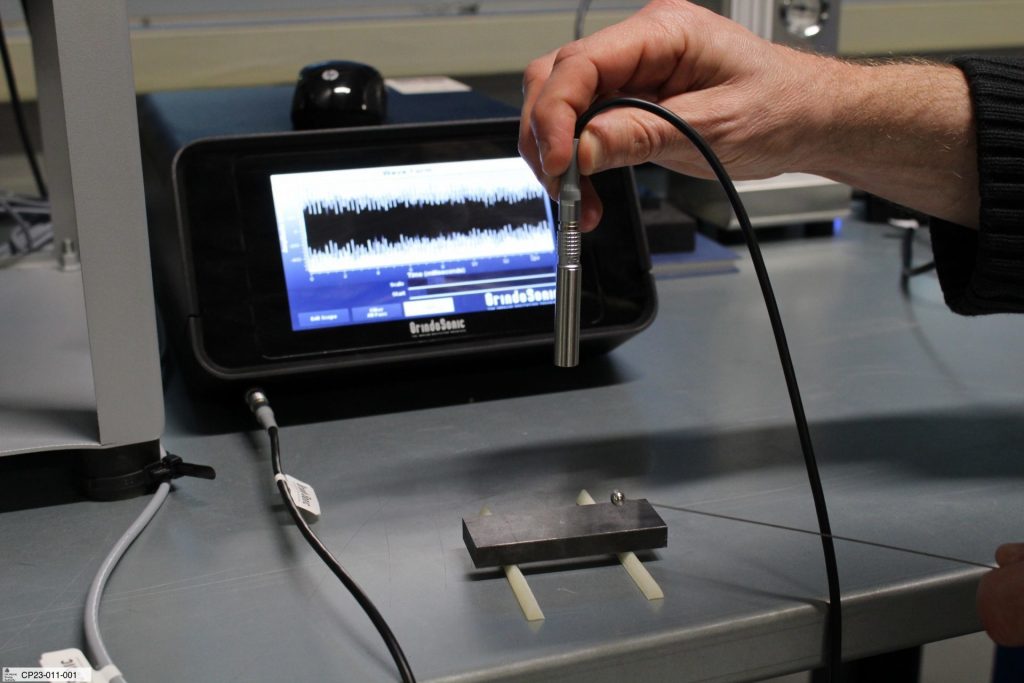

When you tap a material, you inject a burst of energy. That energy spreads inside the part and causes it to vibrate. These vibrations are governed by the part’s internal stiffness and structure—not just the surface.

By analyzing these vibrations, we can see inside the material—revealing its real strength, bonding quality, and structural integrity.

Benefits of Resonance Frequency Testing for Material Stiffness Evaluation

-

Non-Destructive: The part stays intact and usable.

-

Highly Precise: Detects internal issues long before failure.

-

Repeatable: Use again for consistency checks or long-term monitoring.

-

Fast: Full evaluation in seconds—ideal for production lines.

-

Scalable: Works with AI and automation to flag anomalies instantly.

Applications Across Industries

Impulse excitation works anywhere internal structure matters. Even if two parts look identical, they’ll vibrate differently if they were made differently or contain hidden flaws.

-

-

Aerospace: To detect weak bonding in composites and verify stiffness of critical lightweight components.

-

Automotive: For confirming internal consistency in castings, machined parts, and suspension systems.

-

Civil Engineering: To non-destructively assess rebar, concrete beams, and composite structural elements.

-

Additive Manufacturing: For validating printed parts by measuring layer bonding and internal uniformity.

-

High-End Product Authentication: To distinguish genuine luxury components from knockoffs by their vibrational signature.

-

Precision Tools and Mechanical Components: For evaluating tool steels, inserts, gears, and shafts for stiffness and defect consistency.

-

Research and Sensitive Materials: For modulus evaluation and internal condition tracking without consuming the sample.

-

Non-Destructive Testing Advantages in Manufacturing

The Real Physics Behind Vibration and Stiffness

Stiffness is not just a number—it is the physical resistance a material offers when you try to move it. When you introduce motion into a solid object, its internal energy pushes back. The faster that motion settles into a pattern, the stronger that resistance is.

Resonance frequency testing measures this directly. By tapping a material and reading how quickly it vibrates, we’re observing how fast energy can move through its internal structure—how tightly the material holds itself together.

The relationship is simple:

-

A longer sample vibrates slower.

-

A denser sample vibrates slower.

-

A stiffer sample vibrates faster.

When frequency rises, it means the material resists motion more—it’s stronger inside. From this, we extract values like Young’s modulus or shear modulus. The vibration frequencies form naturally, and their exact values are determined by how the material internally transmits and resists motion.

Because this response comes straight from the material’s real structure—no assumptions, no proxies—it provides a direct readout of mechanical integrity. Automated systems calculate this from vibration signals, geometry, and mass, giving repeatable stiffness results every time.

Comparison Table: Resonance Frequency Testing vs. Other Methods

| Method | Preserves Sample | Reveals Internal Structure | Detects Root Causes | Suitable for Automation | Real-Time Ready |

|---|---|---|---|---|---|

| Impulse Excitation | ✅ Yes | ✅ Yes | ✅ Yes | ✅ Yes | ✅ Yes |

| Tensile Testing | ❌ No | ❌ No | ❌ No | ❌ No | ❌ No |

| Ultrasonic Testing | ✅ Yes | ⚠ Partial | ❌ No | ✅ Yes | ✅ Yes |

| Hardness Testing | ✅ Usually | ❌ No | ❌ No | ✅ Yes | ✅ Yes |

Where to Learn More and Get Expert Help

If your organization seeks to modernize quality control or research processes, resonance frequency testing by Grindosonic offers unmatched value for precise, non-destructive material stiffness evaluation.

FAQ

What is resonance frequency testing used for?

It’s used to reveal how strongly a material resists internal motion. By tapping a part and measuring how it vibrates, we directly uncover its stiffness, bonding quality, and structural integrity—without damaging it. This makes it ideal for quality control, failure prevention, and material verification.

How accurate is it for evaluating stiffness?

Extremely accurate—because it measures what the material actually does, not what it’s expected to do. If you know the part’s mass and geometry, and ensure clean, stable measurement, the result reflects the real internal resistance to motion.

Can it be used on composites?

Yes. Composites vibrate differently in different directions. Resonance frequency testing captures that. It reads the part’s directional stiffness—revealing whether layers are bonded, balanced, or showing signs of delamination.

What equipment is used?

Just what’s needed to read motion:

-

A way to tap the part (impactor or actuator)

-

A way to listen (microphone, accelerometer, or laser sensor)

-

Software that reads the frequencies and shows how the structure responded

No cutting, no loading to failure—just watching what the material naturally does.

Is anything damaged during testing?

No. The energy added is tiny—just enough to start vibration. The part stays fully intact, and can be tested again anytime. That’s what makes this method so powerful: it shows internal strength, without touching the outside.

Where can I learn about other non-destructive testing methods?

You can learn about additional non-destructive testing (NDT) methods for evaluating materials and components by visiting resources like The American Society for Nondestructive Testing.

Get Expert Guidance for Advanced Testing Needs

If you’re exploring how to implement resonance frequency testing or improve your quality assurance processes, our team is ready to assist. Contact us today for tailored solutions and expert support in material property evaluation and automated testing integration.