De-Risking Additive Manufacturing Through Non-Destructive Testing Methods

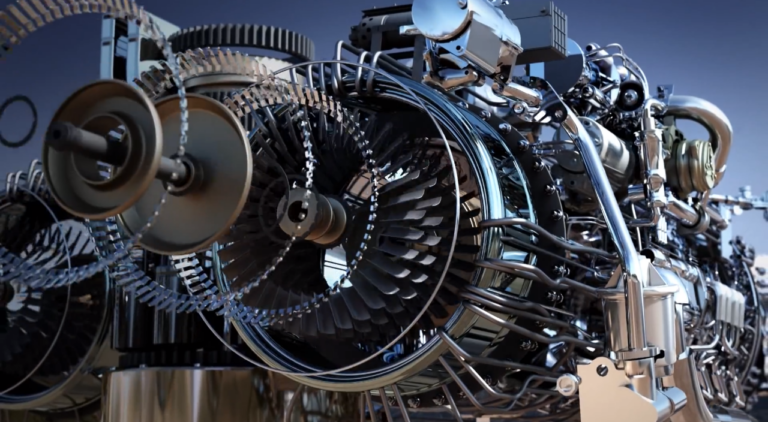

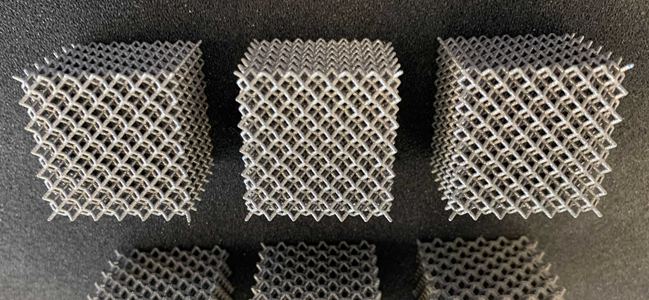

As the adoption of additive manufacturing (AM) grows, so does the need to ensure part integrity and reliability. Non-destructive testing (NDT) methods play a crucial role in de-risking AM processes by identifying potential defects without compromising the components. From ultrasound to X-ray techniques, integrating NDT early in the production cycle enhances quality control, boosts confidence in AM technologies, and ultimately leads to safer, more efficient manufacturing outcomes.