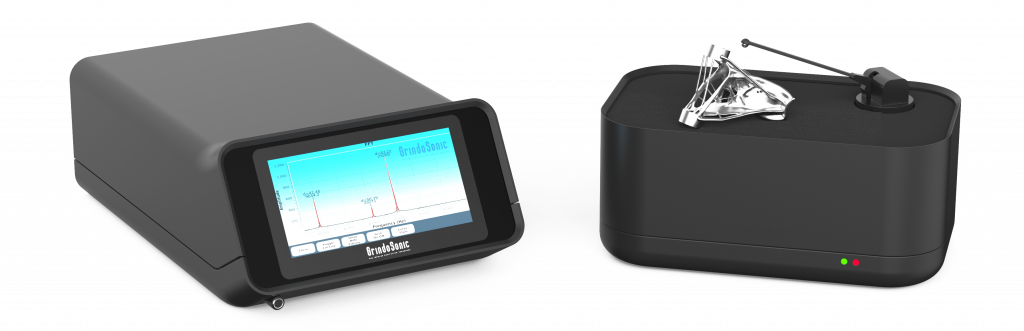

A powerful measurement system for Quality Management and Material R&D

GrindoSonic® develops, manufactures and commercializes non-destructive testing solutions for R&D, Engineering, Production and Quality Control.

13 patents and patents pending protect the IP of GrindoSonic.

The Impulse Excitation

Technique is the basis

for our technology

By applying a single tap, we make a material (test specimen or finished product) resonate. The physical data of this resonance – frequencies and damping – are measured, stored and subsequently converted to the elastic properties of this material. The impulse excitation technique is described in international standards such as ASTM E1876, C1259, C215, E3397 and many more.

We measure mechanical properties of materials, such as Young’s modulus, shear modulus, Poisson’s ratio, relative porosity,

damping capacity and asymmetry. Precise and accurate measurements are guaranteed up to 1600°C.

Property changes and the presence of propagating microcracks are easily

monitored, enabling fast detection of internal defects and property degradation

in an early stage, leading to better products and more efficient production.

Quality Control through fast and accurate measurement of property changes on final

products at the end of the manufacturing process or at any intermediate stage. Our

measurement solutions include automated and production line integrated systems.

Fields of expertise

Specialized knowledge across materials testing, automation, and vibration analysis.

GrindoSonic received Flemish Government Research Grants from Vlaio to develop the Additive Manufacturing (AM) measurement technology.

Upcoming events

You can find us at the following events

25 – 26 March 2026

Coiltech Deutschland

Messe Augsburg

Germany

18 – 21 Nov 2025

Formnext

Stand No. 11.0 – C57

Frankfurt, Germany

Our Satisfied Customers!

You don’t have to take our word for it

Research groups of Materials Engineering at KU Leuven explore, develop and characterize novel materials ranging from composites to 3D printed metals and ceramics. The Grindosonic HT1200 allows the researchers to better understand the microstructural evolution during heat treatment by in-situ monitoring of the mechanical response. (stiffness and damping)

Dr.-Ing. Pierre Vancauwenbergh

KULeuven

After a close, cordial, collaboration with GrindoSonic to demonstrate the benefit of their system, LNE has purchased one of them which has the particularity to enable complementary linear and nonlinear tests, and to display waterfall plot of the results, which is a very evocative way. The collaboration between LNE and GrindoSonic has resulted in two peer review articles and two communications in conferences.

Dr. Habil. Anne-Françoise Obaton

LNE

Different materials are investigated within the scope of various research projects at the Hochschule Bonn-Rhein-Sieg (H-BRS) such as ceramics, metals, intermetallic alloys, and polymers. The IET-system is applied for either high temperature applications (ceramics, metals, etc.) with an automatic device shooter or room temperature applications (polymers) with a manual device shooter.

Prof. Dr.-Ing. Christian Dresbach

Hochschule Bonn-Rhein-Sieg