Impulse Excitation for Additive Manufacturing: Defect Detection in 3D Prints

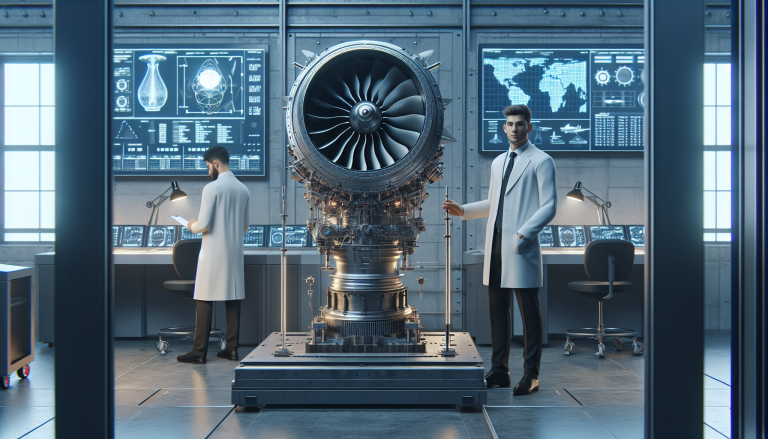

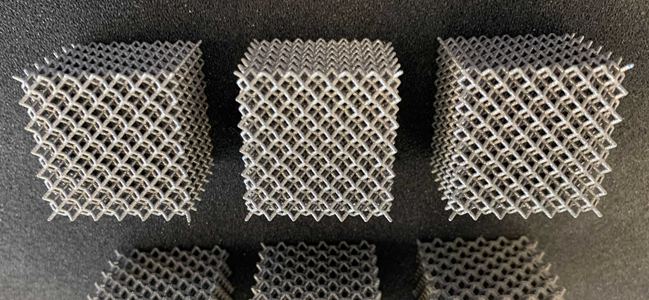

Impulse excitation is revolutionizing defect detection in additive manufacturing. By applying controlled vibrations to 3D prints, this technique identifies anomalies that traditional methods may overlook. The rapid feedback from impulse excitation not only enhances quality control but also optimizes production processes. As industries increasingly adopt additive manufacturing, understanding and implementing these advanced detection methods will be crucial for ensuring the integrity and performance of 3D-printed components.