Listening to Concrete: Stiffness, Damping, and the Science Behind Sound Structures

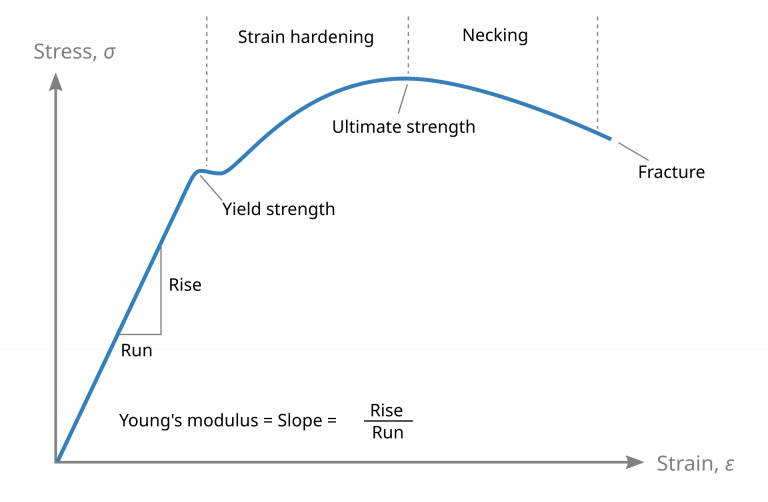

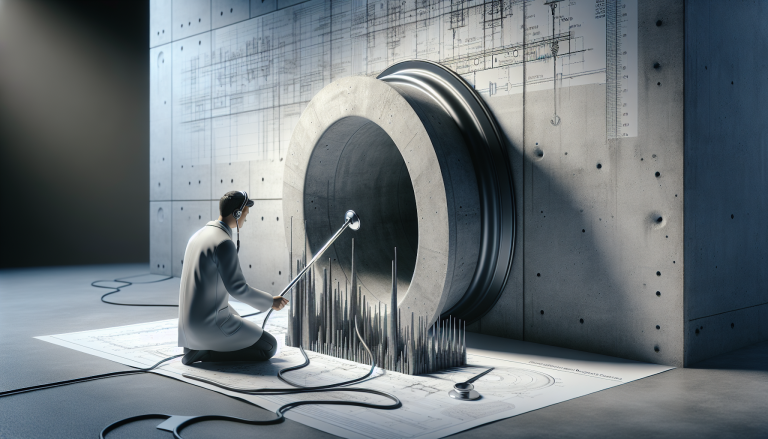

Understanding how stiffness and damping evolve in concrete is essential for assessing durability and long-term performance. In this blog post, we explore how these dynamic properties reveal the internal changes that occur as concrete hydrates, strengthens, microcracks, and heals. By examining the science behind resonance-based monitoring, we highlight innovative, non-destructive approaches that give engineers deeper insight into how concrete builds, transforms, and endures over time.