Luxury watchmaking excellence

The great watchmaking houses offer consistent excellence to their clients, and the quality of their watches is a crucial issue. GrindoSonic, by revolutionizing the Impulse Excitation Technique (IET), ensures optimal mechanical performance to achieve consistent quality.

Mechanical performance

Based on the frequency signature of the tested sample, the GrindoSonic® MK7 instantly calculates its mechanical properties, such as Young’s modulus (E), Shear modulus (G), and Poisson’s ratio (P).

Tests can be carried out manually with the GrindoSonic® MK7 instrument, semi-automatically with a measurement table, or fully automated on a production line with the GrindoSonic® IL system.

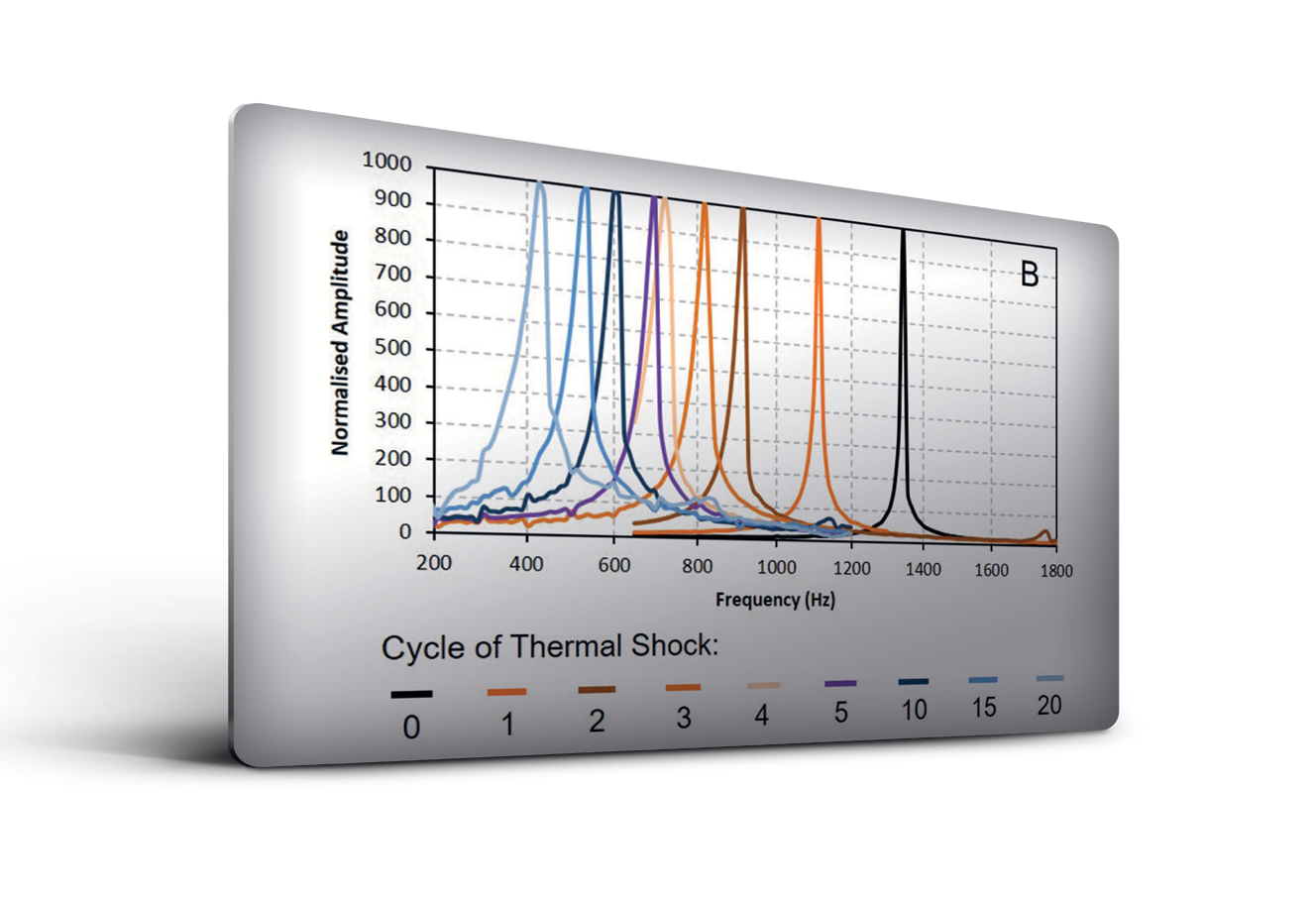

Aging, fatigue tests

Before assembly, ceramic bezels, watch cases, or other components of similar type may present significant differences in stiffness, the presence of microcracks, and porosity. These properties affect the breaking strength and fatigue life of the parts.

The GrindoSonic® MK7 system measures the natural resonance frequency of the bezel (in Hz) and the corresponding damping (the half-height width of the peak) (in Hz).

The first is an accurate measurement of the hardness, composition, and dimensions of the tested sample, while the second measures the total number of cracks present in the object.

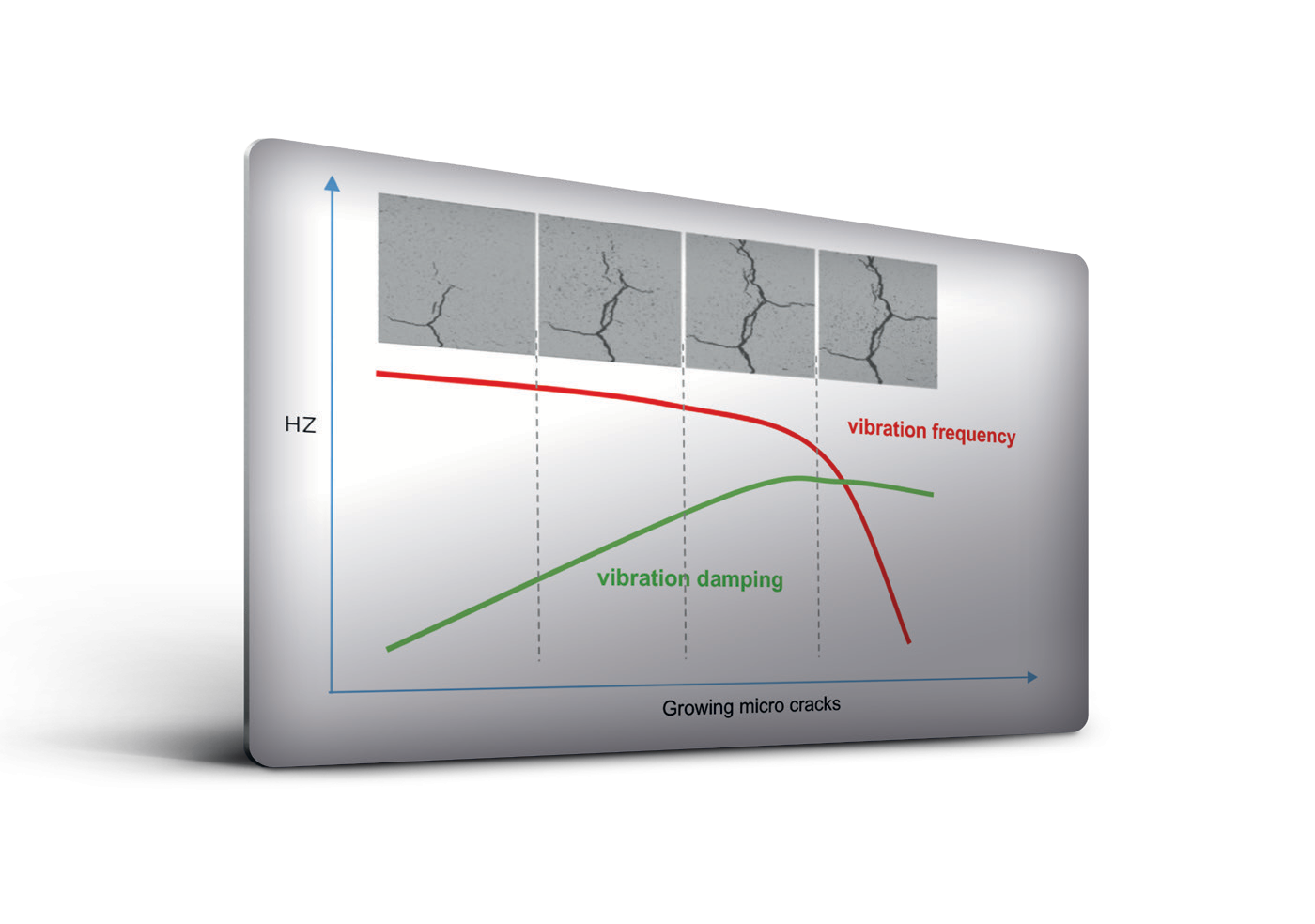

Detection of microcracking

The hardness and composition of a component determine its mechanical properties, such as stiffness and strength. Both have a direct relationship with the resonance frequencies of that specific part.

The GrindoSonic® MK7 system makes it easy to detect dissipative microcracks using a scientific and reproducible method. As can be seen in the accompanying graph, the microcracks in the part caused an increase in damping and a decrease in resonance frequency.

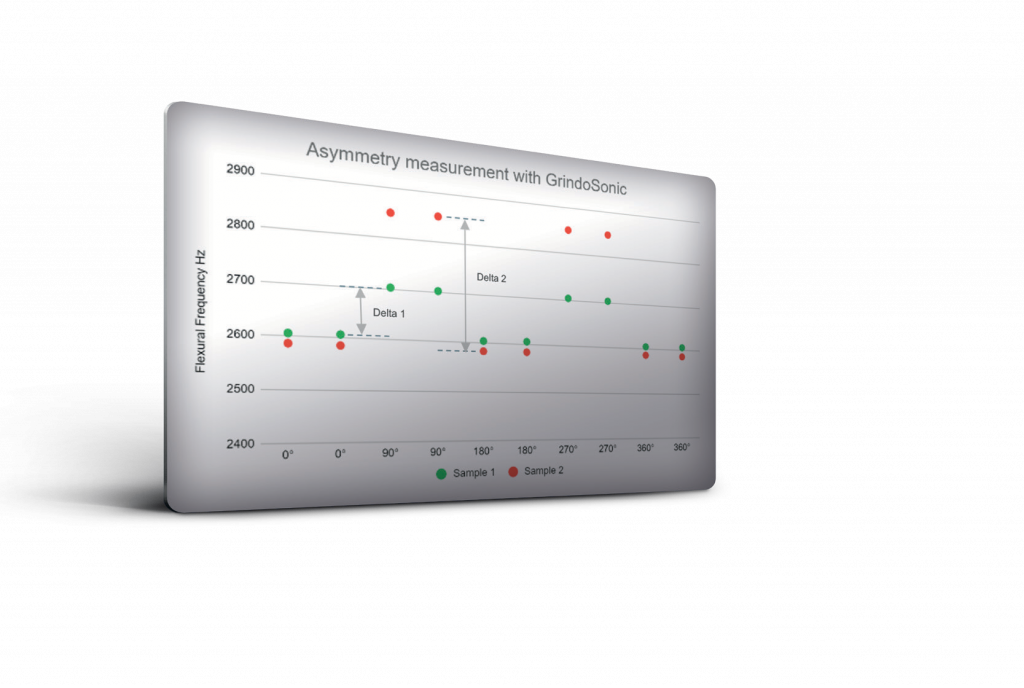

Measurement of asymmetry and small defects

In addition, the GrindoSonic® MK7 system, together with a measurement table, makes it possible to measure the asymmetry of a circular part, such as a ceramic bezel.

When defects are present in the material, they cause an imbalance in the part.

The offset, the delta between frequencies, is a direct measurement of imbalance or asymmetry of the part. If the part has nominal asymmetry (for example, due to raised numerals on a bezel), the system will measure the asymmetry deviation compared to the nominal value caused by defects.

The measurement resolution of 1 ppm detects minimal defects leading to imbalances.

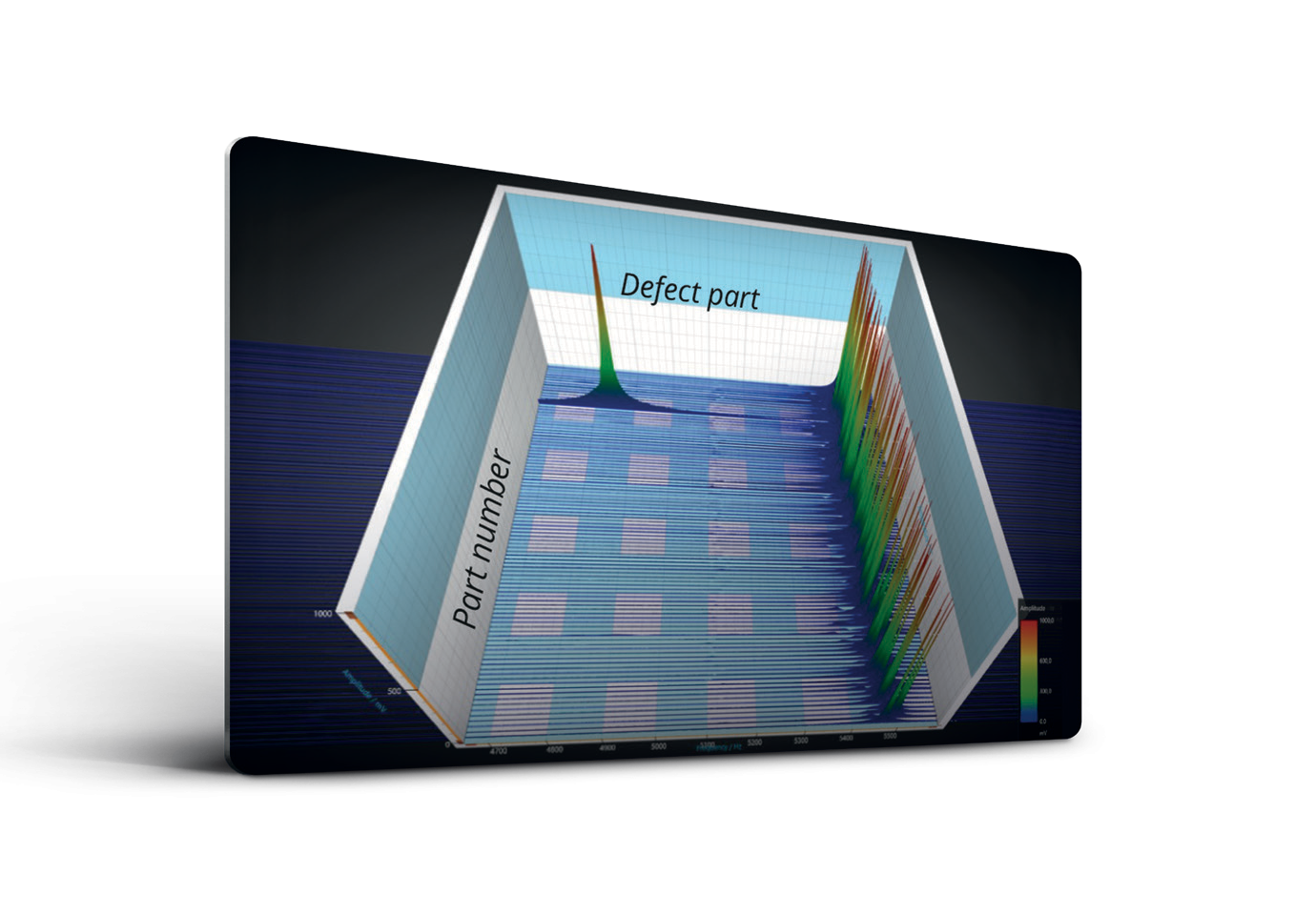

Production quality consistency

The GrindoSonic® MK7 system measures the “frequency signature” of a sample, which can be checked against the reference signature of a good sample.

Components that fall, as illustrated in the attached diagram, within a tolerance band defined by the user (in frequency and damping) will be accepted or rejected.

Optimization of individual production steps

By measuring the parts before and after each key stage of the manufacturing process, it becomes possible to analyze the specific differences of each part at each stage. By measuring the vibration of 30 parts, we can determine the impact of each manufacturing step, including sintering (which consolidates powder into a solid form), grinding (which refines the geometry of the part), and polishing (which ensures the surface finish).

These data then allow us to target improvement efforts to optimize the quality and precision of each component.

Conclusion

In conclusion, the new GrindoSonic® MK7 measurement system guarantees optimal mechanical performance, consistent quality, and optimized manufacturing processes for high-end watches.

Its ability to detect defects as small as one part per million (ppm) makes it an ideal solution for companies wishing to maintain high standards of quality and reliability.