GrindoSonic® in Technical Ceramics

A convenient and non-destructive measurement technique for Materials Research and Product Quality Consistency.

Technical ceramics, known for their superior properties such as stiffness, high temperature resistance, chemical and wear resistance, insulating properties are also brittle and sensitive to cracks. GrindoSonic provides a powerful measurement technique for Research and Quality Control. The technique is based on measuring the resonance

vibrations of materials and products that are converted to mechanical properties as described in the ASTM E1876. The resonance vibrations are defined by frequency and damping which are unique for the material or product under test. Many patents and patents pending protect the intellectual property of GrindoSonic.

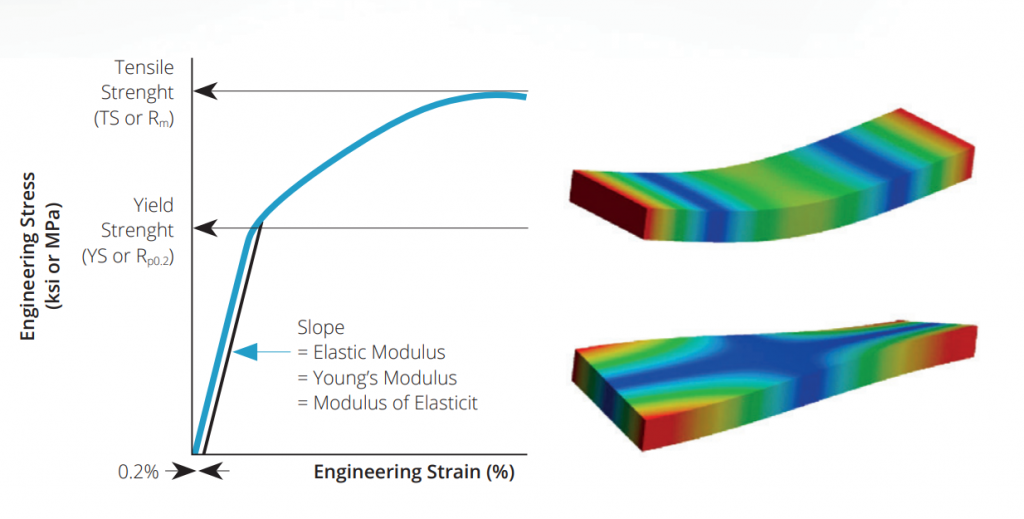

Materials Characterization

The GrindoSonic® MK7 system measures Young’s and Shear modulus, Poisson’s ratio and Internal Friction of materials in a fast, accurate and non-destructive way. By making test-bars with newly developed materials, the mechanical elastic properties can be easily determined and compared.

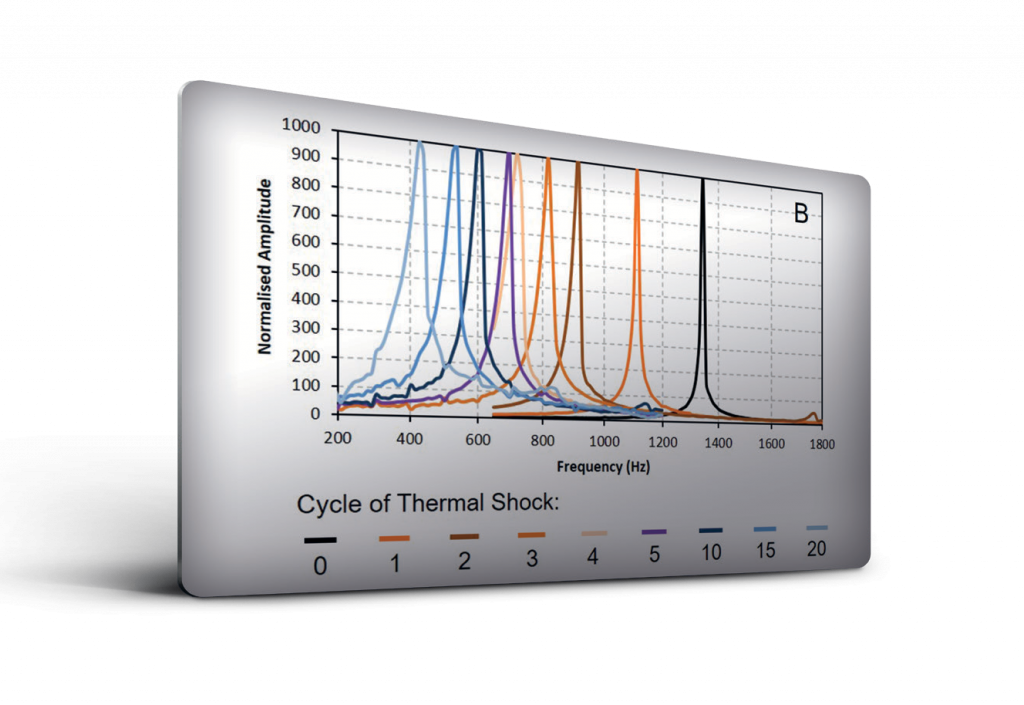

Ageing, Fatigue testing

Because of its non-destructive nature, in-house monitoring of properties’ evolution has never been easier and less time consuming. Think about thermal cycles, ageing and fatigue testing or any other treatment by measuring the samples before and after.

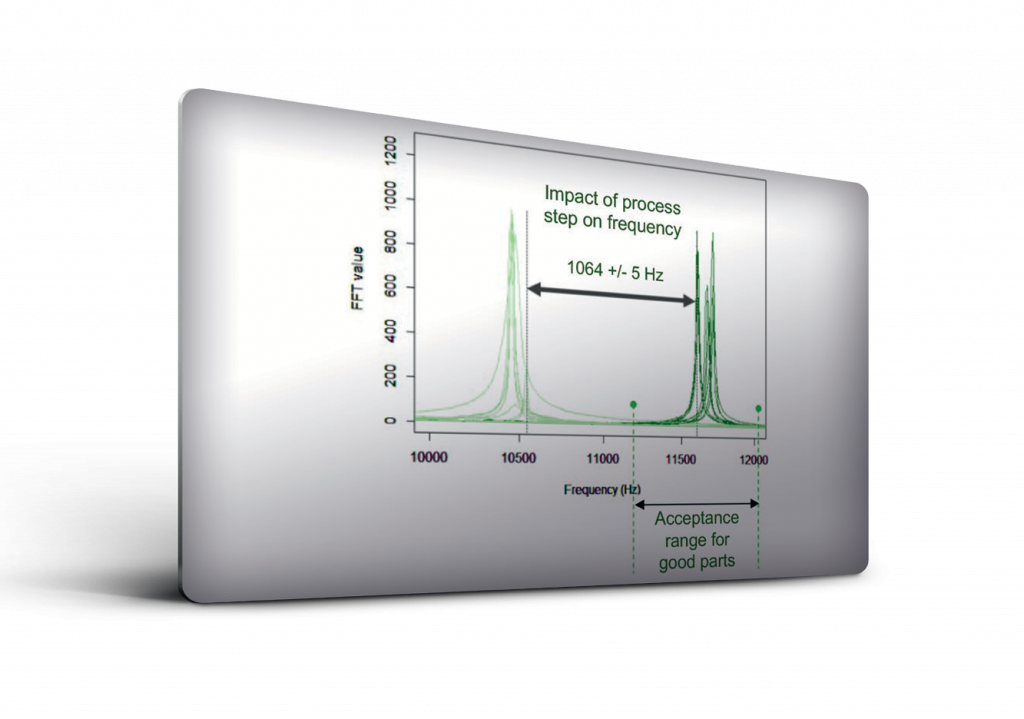

Process Control and Optimization

During a firing- or sintering-process, properties change. Using the GrindoSonic® technique, the frequency shift becomes an accurate metric for monitoring and optimizing the above processes. A similar example is the process evaluation of HIP treatments, applied to reduce the porosity after additive manufacturing.

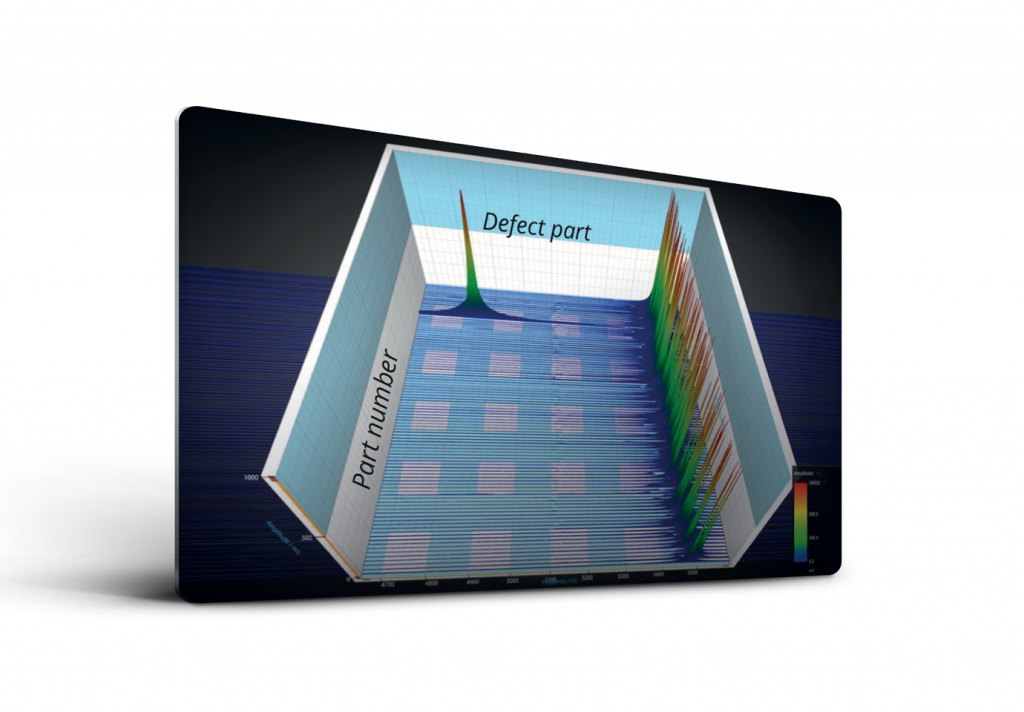

Quality Control

Identical parts show the same resonance vibration pattern. Deviations in frequency and/or damping reveal anomalies in the parts which are affecting the mechanical performance of the product. Setting boundary conditions for frequency and damping allows for 100% Quality Control.

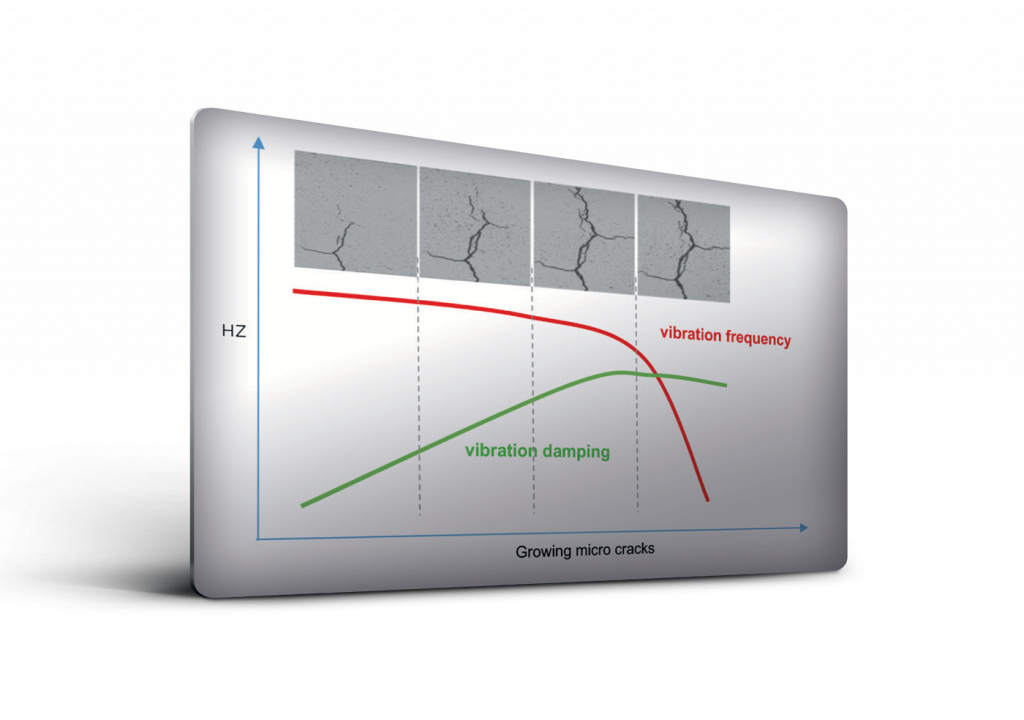

Detection of micro-cracks

Micro-cracks in a product or sample have a direct impact on the damping of the resonance vibration. Growing cracks will further increase the damping and at a certain point, the integrity of the material will degrade resulting in lowering frequency measurements.

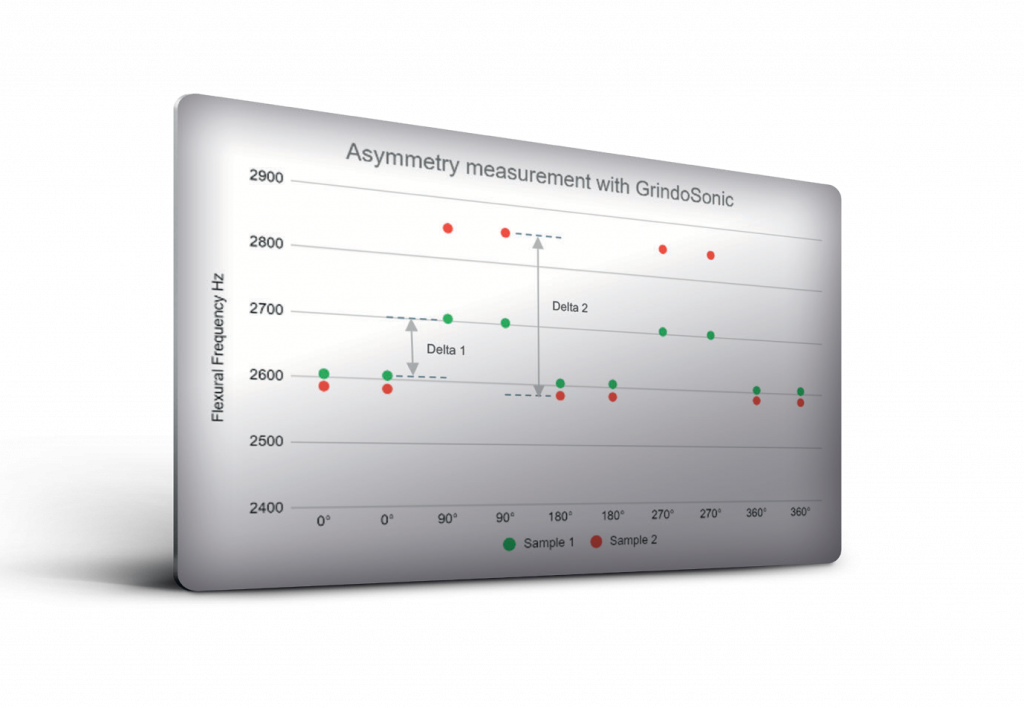

Asymmetry

Symmetric parts like tubes, cylinders or discs can be tested for quantifying their asymmetry. The asymmetry is typically caused by:

- geometric instability e.g. ovality

- variations in density over the object

- presence of internal defects like cracks, voids, etc.

The distance between the two frequency peaks (delta) is a metric for the asymmetry.