New options for non-destructive Quality Control and Process Optimization.

For a long time, manufacturers of grinding products have known that the functional hardness of their products is quantified by measuring the stiffness. Since then, GrindoSonic® has become the standard for determining Young’s modulus of grinding products with its non-destructive, fast and accurate measurement technique. The technique is based on measuring the resonance vibrations of materials and products

and converting into mechanical properties as described in various grinding standards as well as ASTM 1876. The resonance vibrations are defined by frequency and damping which are unique for a material or product. Besides the standard grinding products, also resin-based, CBN or diamond-based materials are quality tested and measured for their elastic properties.

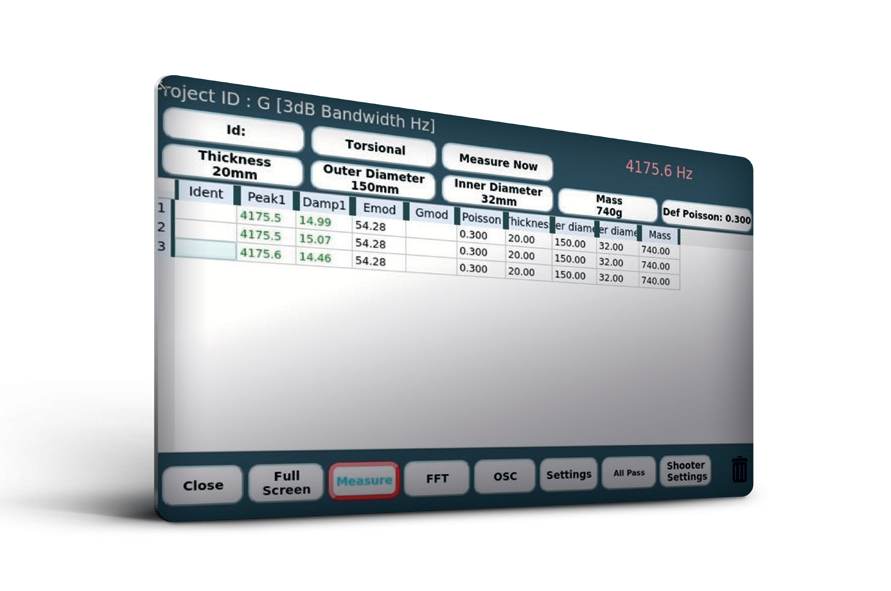

Young’s modulus measurement

Today, the GrindoSonic® MK7 measures and calculates instantly the Young’s modulus without manual conversion in spreadsheets. Dimensions and weight can be easily entered by connecting scale and caliper to the system. Just tap and read the results.

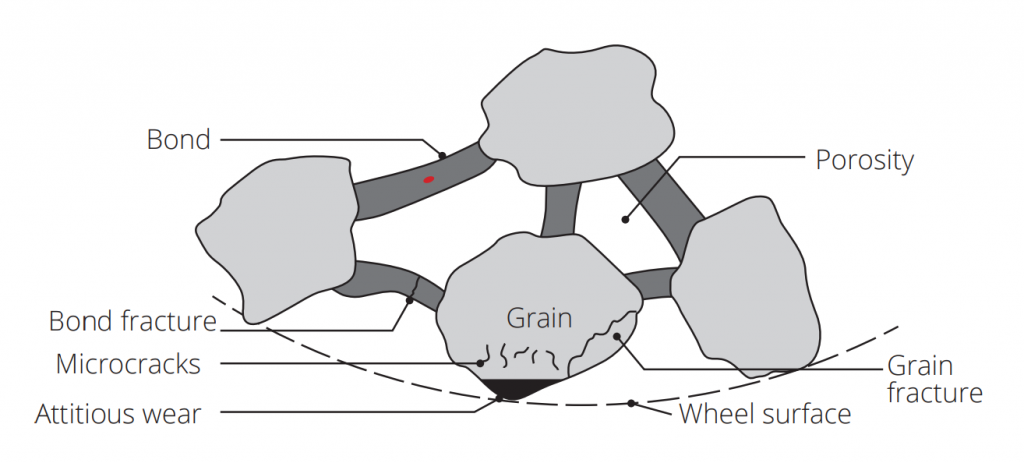

Overall Quality Correlation

The resonance vibration measurements give an accurate and complete insight into the full quality of your product. The frequency translates to the stiffness (Young’s modulus), hardness, grain holding power and porosity. The damping values relate to microcracks and bond failures.

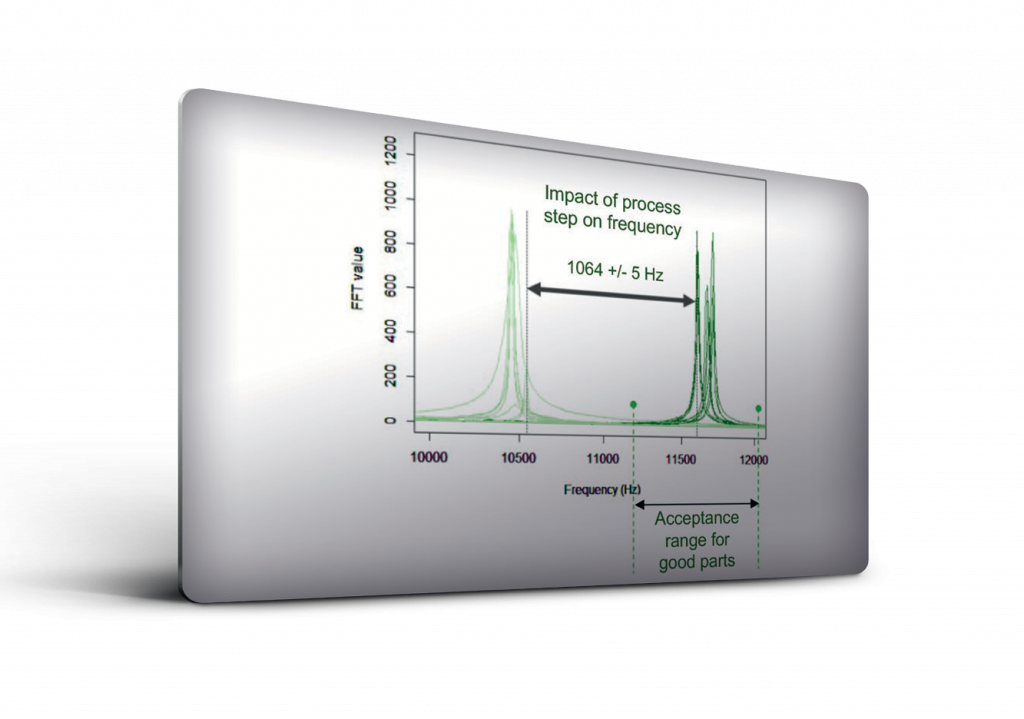

Process Control and Optimization

During a firing- or sintering-process, properties change. Using the GrindoSonic® technique, the frequency shift becomes an accurate metric for monitoring and optimizing the above processes. A similar example is the process evaluation of HIP treatments, applied to reduce the porosity after additive manufacturing.

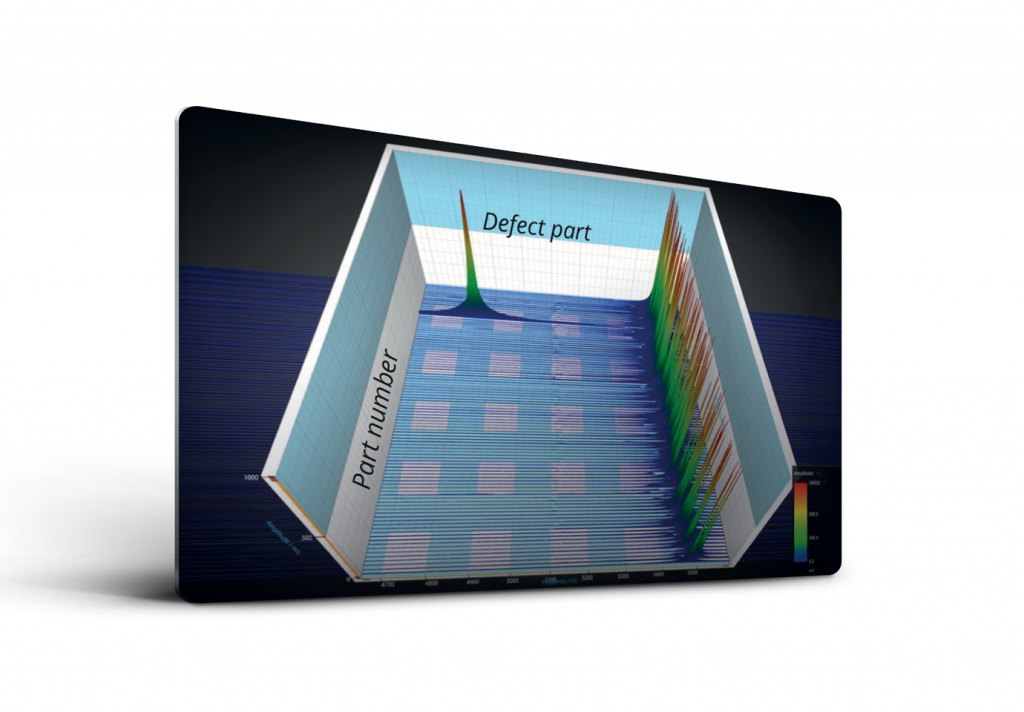

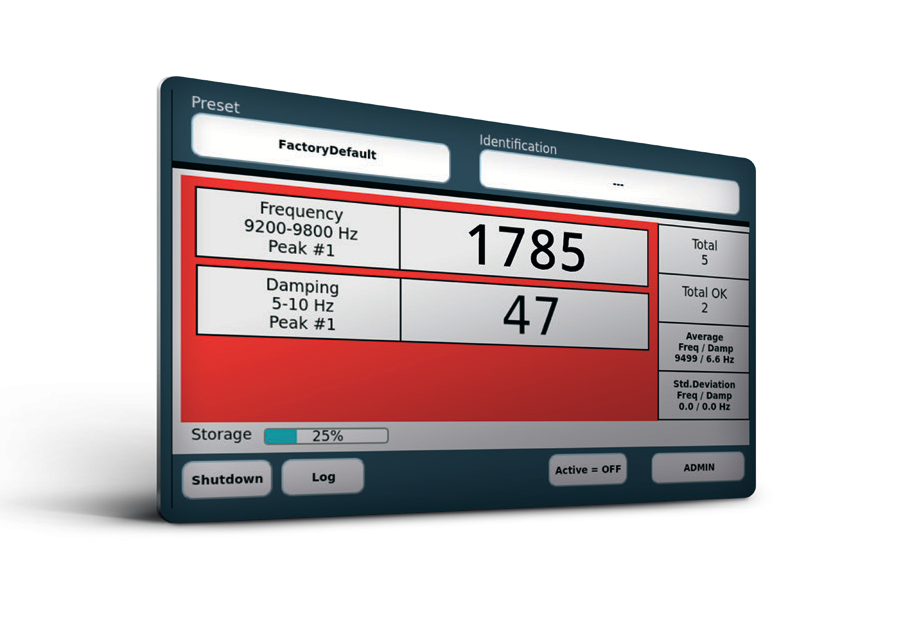

Quality Control

Identical parts should show the same resonance vibration pattern. Deviations in frequency and/or damping reveal anomalies in the products which are affecting their mechanical performance. Setting boundary conditions for frequency and/or damping allows to distinguish good from bad parts. The measurements can be automated.

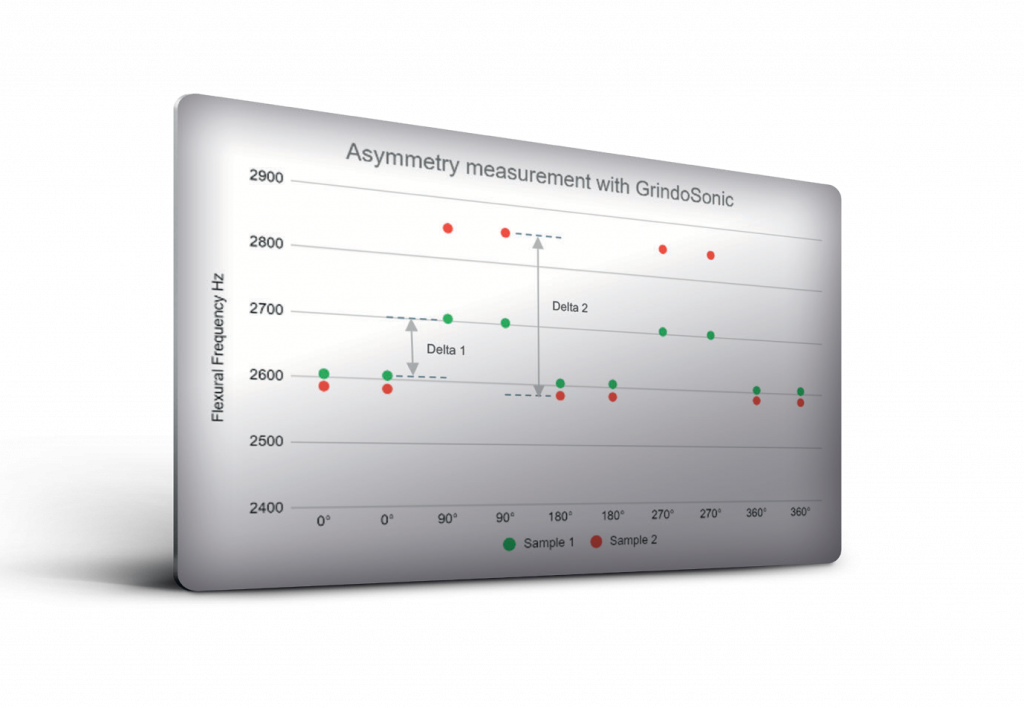

Asymmetry

Symmetric parts like grinding wheels can be tested to quantify their asymmetry, which is typically caused by:

- geometric instability e.g. ovality

- variations in density over the object

- internal defects like cracks, voids, etc.

The distance between the two frequency peaks (delta) is a metric for the asymmetry.