The ultimate measurement tool for additive manufacturing quality improvement.

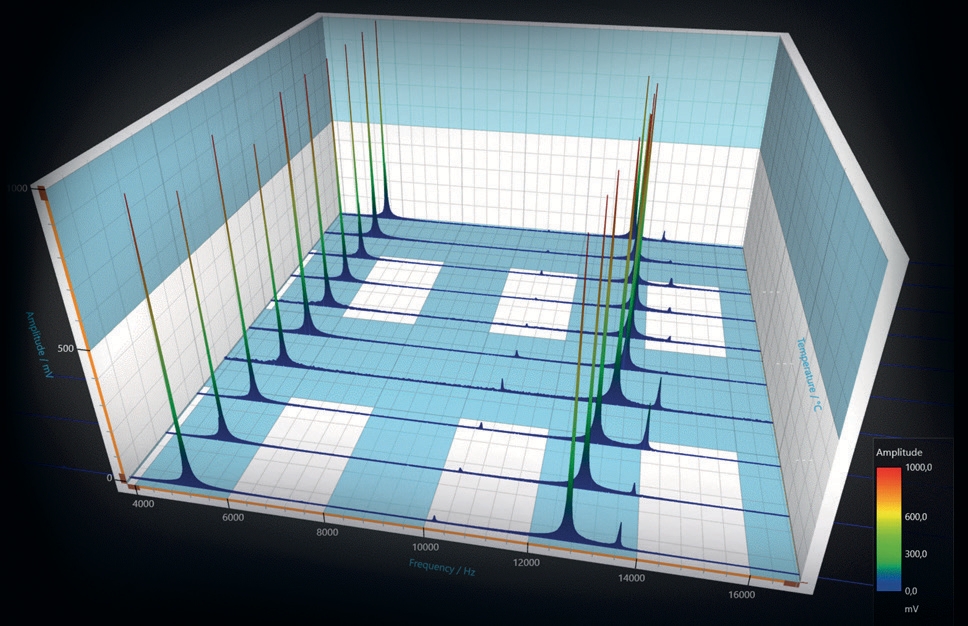

GrindoSonic® provides a powerful measurement technique for Research and Quality Control. The technique is based on measuring the resonance vibrations of materials and products that are converted to mechanical properties as described in the ASTM E1876 and E3397-23.

The resonance vibrations are defined by frequency and damping which are unique for the material or product under test. Multiple patents and patents pending protect the intellectual property of GrindoSonic.

Additive Manufacturing

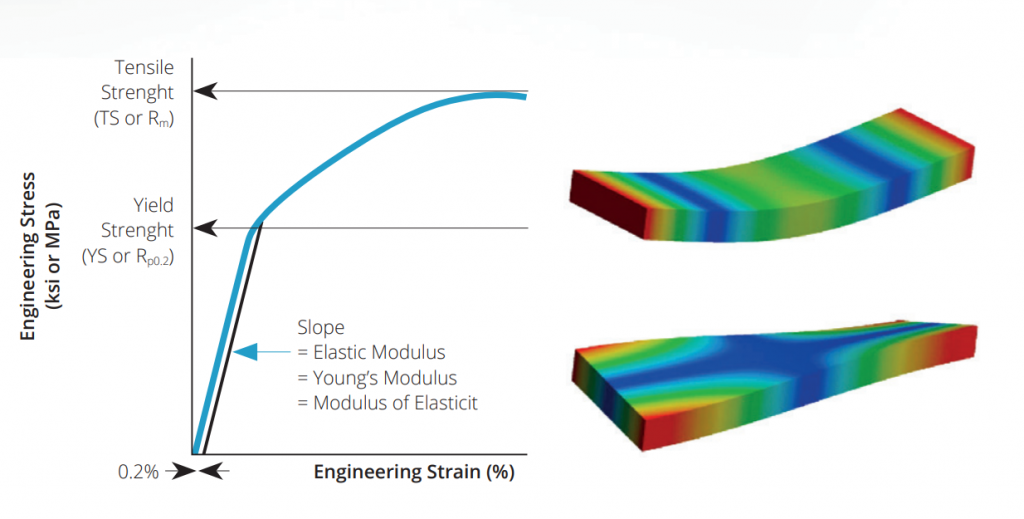

The GrindoSonic® MK7 system measures Young’s and Shear modulus, Poisson’s ratio and Internal Friction of materials in a fast, accurate and non-destructive way. By making test-bars with newly developed materials, the mechanical elastic properties can be easily determined and compared.

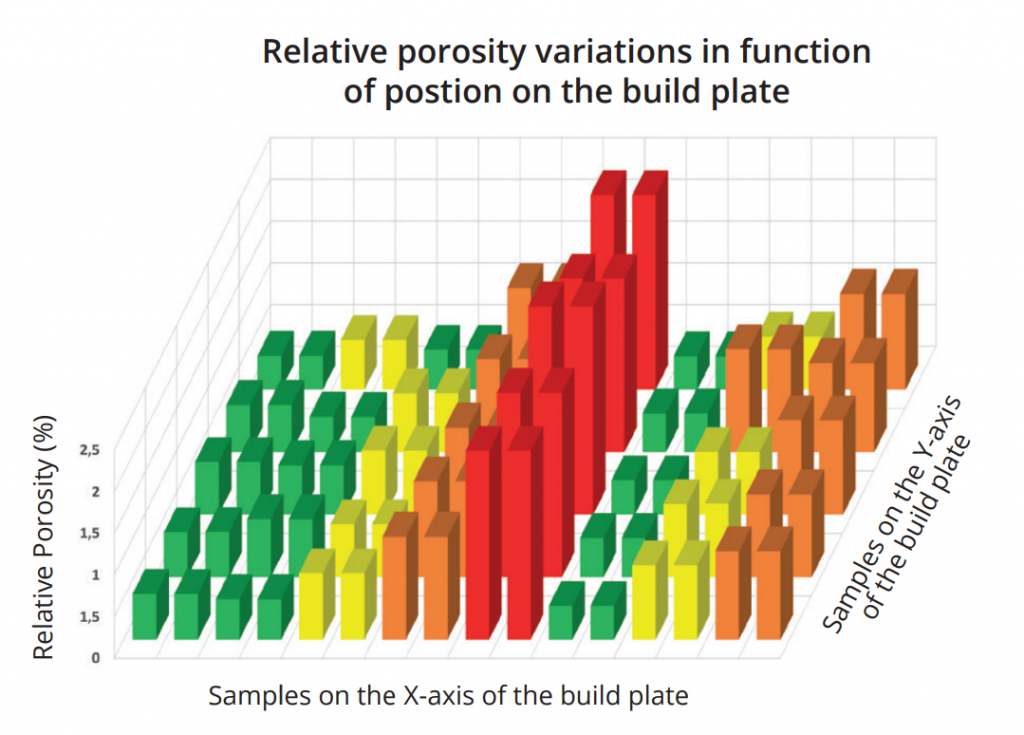

Validation of printing systems & processes

The printing parameters and settings have a strong influence on the final result of a build. The GrindoSonic® MK7 offers a simple and quick validation of the consistency of an AM machine. Our technique also enables the process monitoring to guarantee uniform products over time. This can be done by printing reference bars on strategic locations of the build to measure process consistency in the whole build.

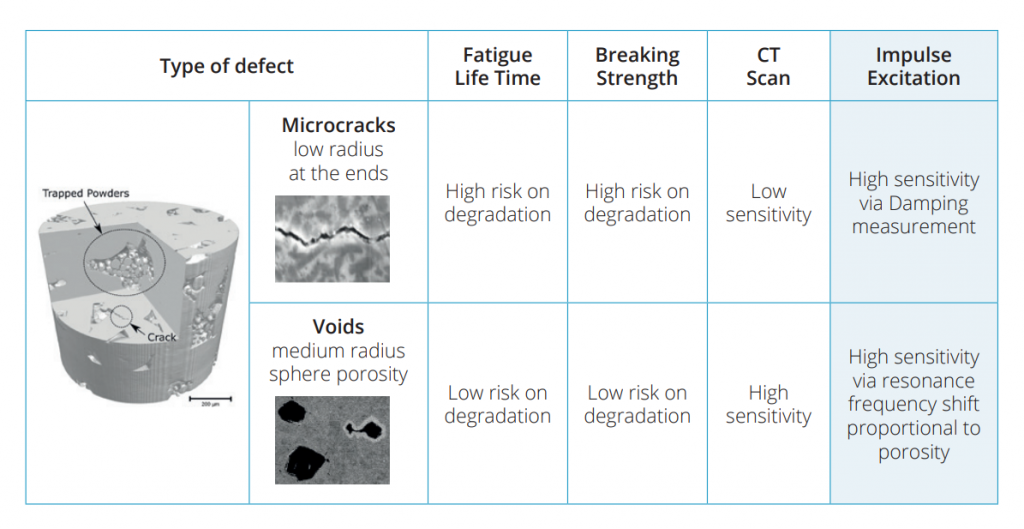

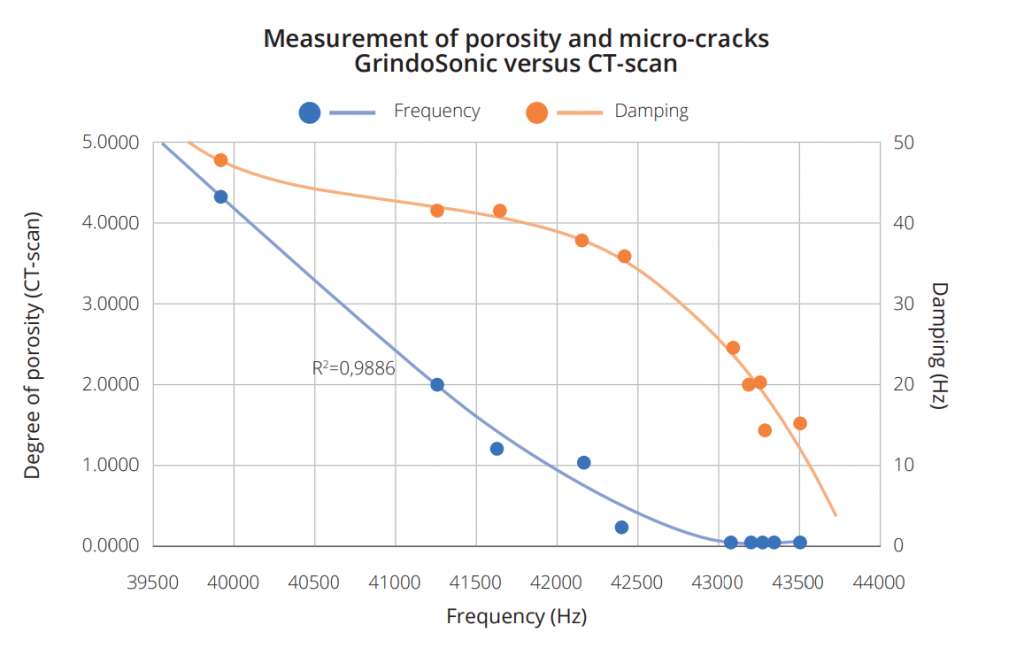

Porosity and micro-crack quantification

GrindoSonic® measures porosity and dissipative micro-cracks. Micro-cracks do propagate and finally cause failure of the parts. We established a good correlation of our measurements with both porosity and micro-cracks at lower cost, faster and with a higher resolution.

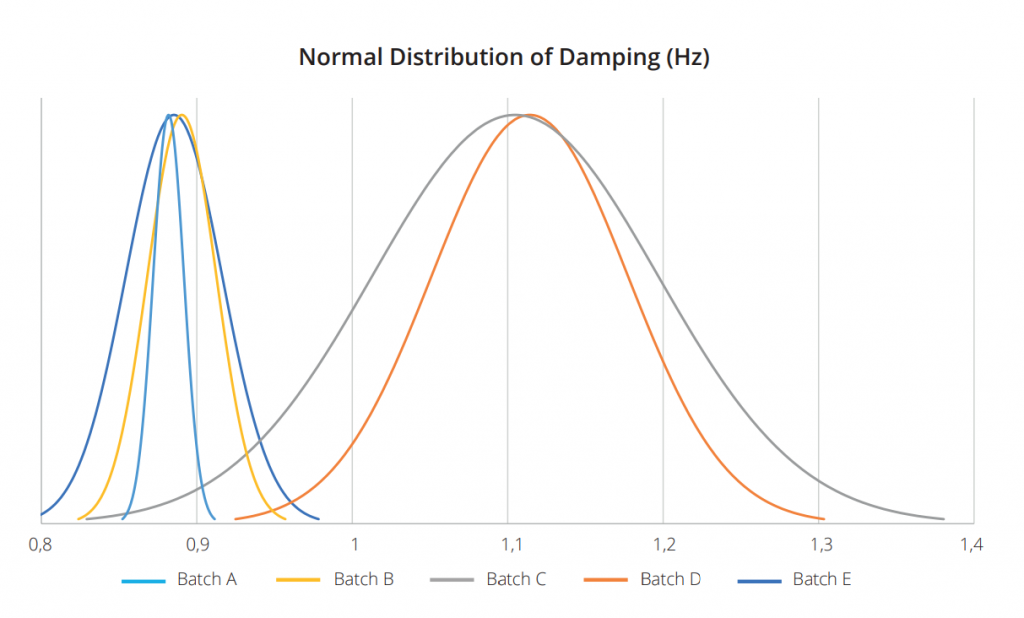

Batch-to-batch production consistency

Changes in frequency and/or damping indicate changes of elastic and mechanical properties. All processes should be standardised to produce high-quality finished products with assured batch-to-batch consistency. GrindoSonic® measurements provide insights in value shifts and the spread of production batches. The effect of changing single parameters can be quantified instantly.

Quality control of final products

A supplier of 3D-printed products wants to achieve the properties that are specified by the customer. In order to validate that the mechanical properties are within tolerance, the GrindoSonic® MK7 identifies property deviations among finished parts, fast and accurately. The technique is available as a fully automated system or can be integrated in your production line.