Key Takeaways

Grinding wheels made it clear: why impulse excitation works is simple—it reveals internal integrity with a single tap.

-

Grinding performance is tightly linked to stiffness.

-

Even small deviations in material properties affect tool life, safety, and finish quality.

-

Impulse excitation measures exact stiffness through resonance, mass, and dimensions.

-

It reveals hidden flaws without damaging the disc.

-

This foundational use case launched GrindoSonic.

Why Tapping Grinding Wheels Mattered First

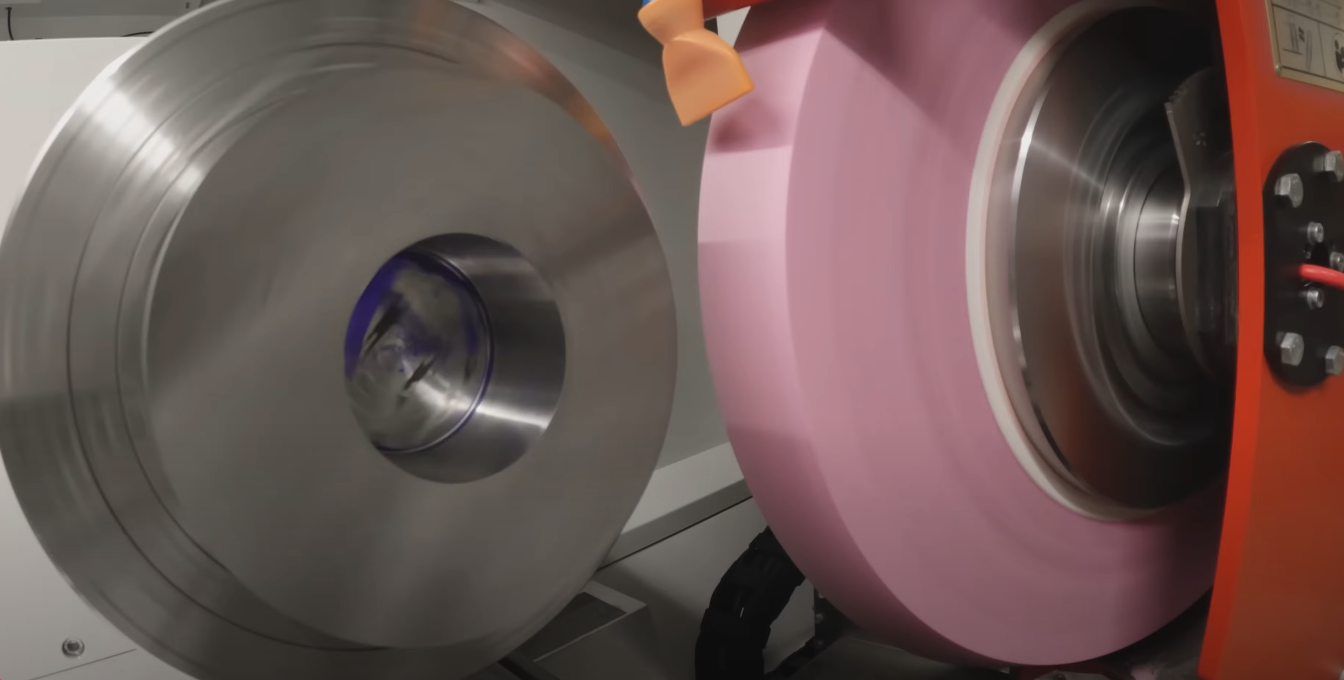

In high-speed grinding, precision is everything. A wheel that’s too soft burns the part. Too hard, and it shatters. Even surface finish and tool wear are affected by stiffness. That’s why in the early days of GrindoSonic, this was where the need for non-destructive testing was too strong to ignore.

Understanding Stiffness, Hardness, and Strength

These four properties are often confused, but they measure very different aspects of material behavior:

-

Stiffness (measured by Young’s modulus) is how much a material resists bending or deformation under load. It defines how a grinding wheel reacts in motion.

-

Hardness is the resistance to surface indentation or abrasion. It affects wear, but not how the wheel flexes or vibrates.

-

Strength refers to the maximum stress a material can take before breaking.

- Porosity is the amount and size of empty space (pores) between the abrasive grains and bonding material. It plays a critical role in coolant flow, chip clearance, and wheel wear, all of which directly impact grinding performance.

Impulse excitation measures stiffness, not hardness or strength, because stiffness governs how energy moves inside the material. That’s what vibration reveals.

Stiffness drives grinding behavior. In many cases, we can infer hardness and strength from the way a part vibrates. But only stiffness has a direct, undeniable link to vibrational behavior. That’s why impulse excitation is so causally strong, it measures the property that actually governs how the material responds to motion.

How Impulse Excitation Works

Impulse excitation works based on real material behavior. A simple mechanical tap sends vibrations through the disc. When we measure those resonance frequencies—and combine them with the part’s mass and dimensions—we calculate its exact elastic modulus. No cutting. No stress testing. Just a clear read on real mechanical behavior.

What the Tap Reveals

Each disc has a unique vibration signature. Cracks, firing flaws, porosity, or inconsistent bonding all distort that signal. A clean, expected response means reliability. A shifted or unstable one means risk. With impulse excitation, we detect these flaws before the wheel even touches a machine.

Benefits Compared to Traditional Methods

Before impulse excitation, testing grinding discs was mostly destructive—or subjective. Some methods used bending or ball pressure to fracture test pieces. Others relied on human ears: tapping a disc and listening for a “ring.”

Grinding wheels made it clear: why impulse excitation works is because it replaced guesswork with measurable precision. It provides:

-

Non-destructive full-part testing

-

Accurate stiffness values (E-modulus) using frequency, mass, and size

-

Early flaw detection: inner cracks, porosity, bonding issues

-

Repeatable, automated results

-

Scalable integration into production and QC environments

Broader Impact and Expansion

This wasn’t just our first application. It was the moment we proved that materials would tell the truth—if you asked the right way. From grinding wheels, GrindoSonic expanded into metals, composites, ceramics, and additive manufacturing. But it all started with a single need: to measure internal stiffness without causing any damage.

Grinding wheels made it clear: why impulse excitation works—and why GrindoSonic was built to deliver it.

For a deeper look at how impulse excitation reveals stiffness and internal flaws across industries, read our article on testing material strength through a tap.

FAQ

Why is stiffness so critical in grinding?

Because it controls everything: stock removal, surface finish, heat generation, and tool safety. The wrong stiffness leads to poor performance or failure.

How does impulse excitation actually work?

We tap the part, measure its natural vibration frequencies, and use its mass and dimensions to calculate exact stiffness (E-modulus).

Can this detect internal cracks or flaws?

Yes. Any change in structure—like cracks, poor bonding, or porosity—shifts the vibration signature. We detect those changes instantly.

Is this better than traditional QC?

Much better. It’s fast, non-destructive, repeatable, and precise. Unlike old methods, it doesn’t rely on visual cues or subjective judgment.

What equipment is used?

Just what’s needed to read motion:

-

A way to tap the part (impactor or actuator)

-

A way to listen (microphone, accelerometer, or laser sensor)

-

Software that reads the frequencies and shows how the structure responded

No cutting, no loading to failure—just observing how the material naturally responds.

Is anything damaged during testing?

No. The energy added is tiny—just enough to start vibration. The part stays fully intact and can be tested again anytime. That’s what makes this method so powerful: it shows internal strength without ever touching the surface.

Where can I learn about other non-destructive testing methods?

You can learn about additional non-destructive testing (NDT) methods for evaluating materials and components by visiting resources like The American Society for Nondestructive Testing.

Get Expert Guidance for Advanced Testing Needs

If you’re exploring how to implement resonance frequency testing or improve your quality assurance processes, our team is ready to assist. Contact us today for tailored solutions and expert support in material property evaluation and automated testing integration.