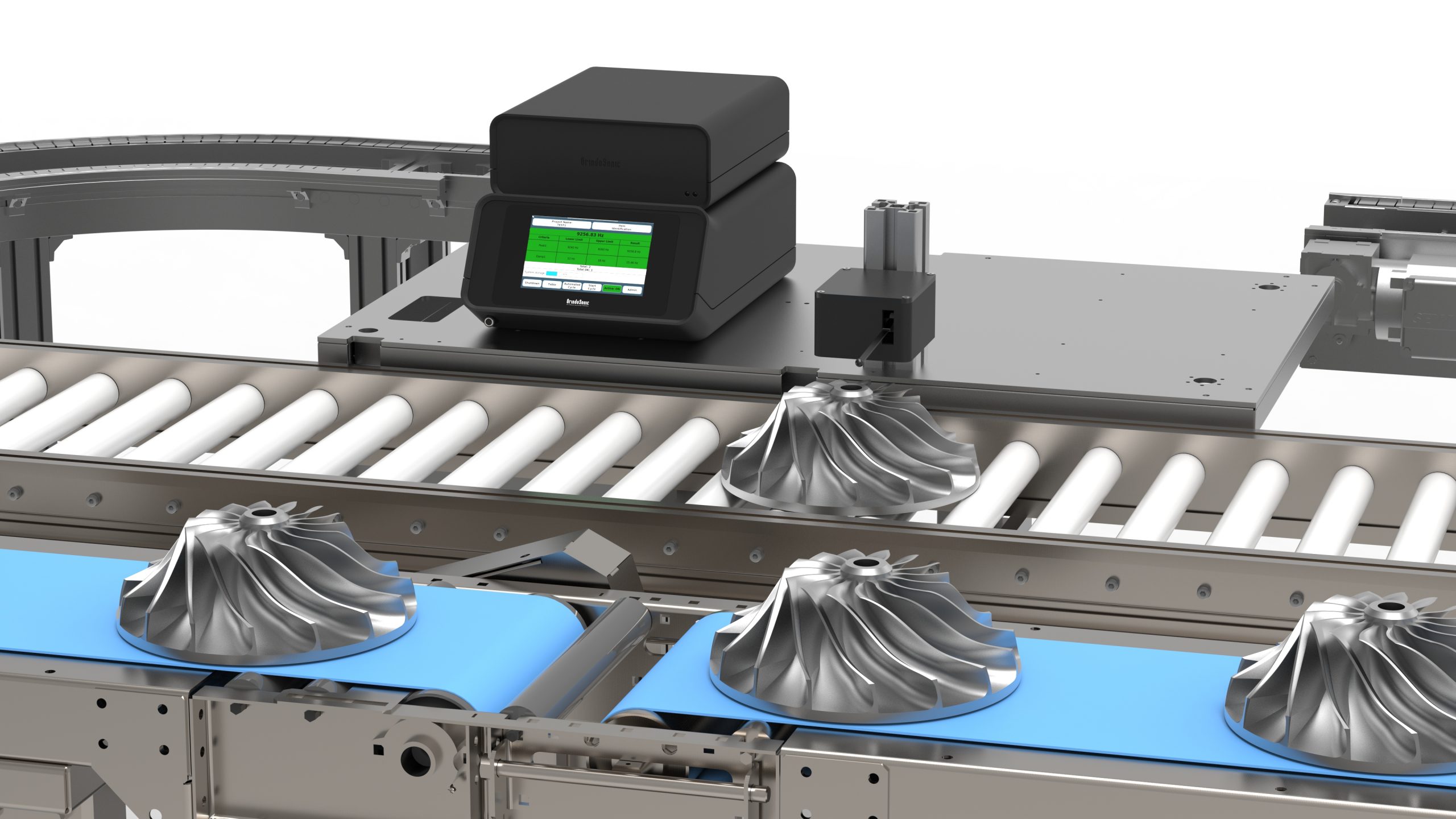

In-Line System

Our in-line measurement system based on impulse excitation provides real-time testing of materials during production processes. Using an impulse hammer and a piezoelectric sensor, we measure dynamic properties such as stiffness, damping, and natural frequencies as the materials move along the production line.

With customizable software and automated data collection, our system can help identify quality control issues and improve production efficiency.

Features

Automated data collection

Measuring each produced part in seconds, data collection from all your parts becomes easy.

Customizable software

Our software allows you to set the parameters describing a perfect part. When the part doesn’t comply to the impulse test, it can be removed from the line.